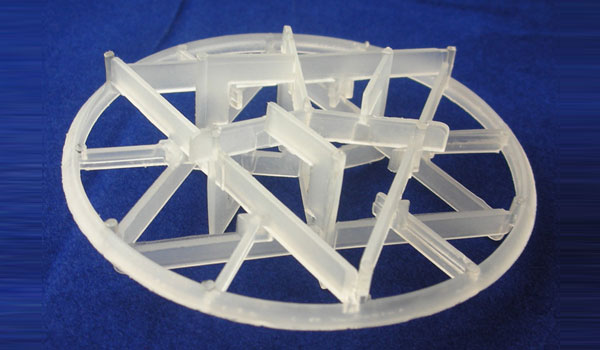

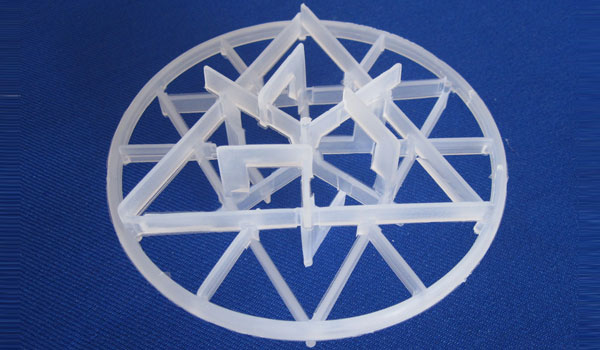

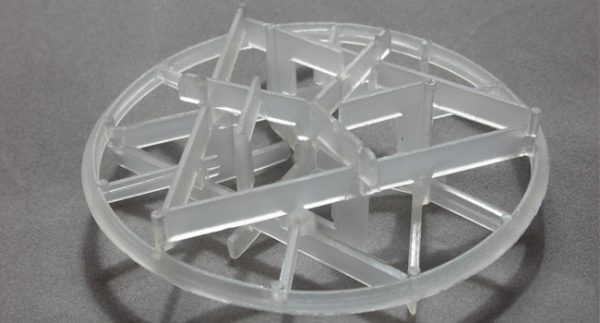

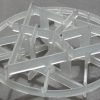

Plastic Snowflake Ring

Plastic Snowflake Ring

For the maximum tower of performance, Snowflake Ring offers a unique combination of superior separation efficiency and high capacity. It is widely applied in the Chemical Processing Industry, including Chlorine and Bromine Production. It is the preferred mass transfer device for emergency scrubbers in processes involving halogens because of its superior performance over a wide operating range. It is often used in environmental applications, such as scrubbing and stripping.

描述

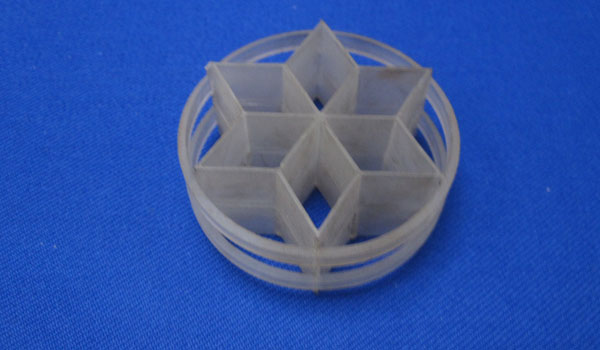

Parameters of Plastic Snowflake Ring

| Performance/Material | PE | PP | RPP | PVC | CPVC | PVDF | ||

| Density(g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 | ||

| Operation Temp(℃) | 90 | >100 | >120 | >60 | >90 | >150 | ||

| Chemical Corrosion resistance | Good | Good | Good | Good | Good | Good | ||

| Compression Strength(MPa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 | ||

Advantages of Plastic Snowflake Ring

- High Free Volume

- Low Pressure Drop

- Low mass-transfer unit height

- High flooding point

- Small specific gravity

- High mass transfer efficiency