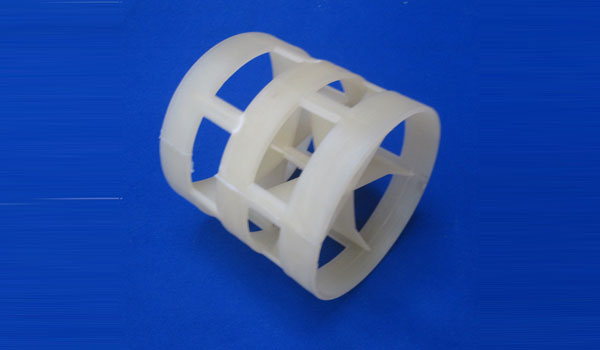

Plastic Pall Ring

Plastic Pall Ring

NAIKE CHEMICAL Plastic Pall Ring is versatile. This product was advanced on the basis of Plastic Rasching Ring, and compared with it, both of them have similar cylindrical dimensions but the Plastic Pall Ring has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop.

描述

Plastic Pall Ring Packing Specification

Technical Parameter

| D×H×δ mm | Specific area m2/m3 | Void Rate % | Bulk Number g/m3 | Package Density (kg/m3) | F factor m-1 | |||

| 16*16*1 | 188 | 91 | 170000 | 85 | 275 | |||

| 25*25*1.2 | 175 | 90 | 53500 | 69 | 239 | |||

| 38*38*1.4 | 115 | 89 | 15800 | 63 | 220 | |||

| 50*50*1.5 | 93 | 90 | 6500 | 52 | 127 | |||

| 76*76*2.6 | 73.2 | 92 | 1927 | 41 | 94 | |||

| 100*100*3 | 52.8 | 94 | 1000 | 32 | 82 | |||

Physical & Chemical Properties

Plastic pall rings are available in various materials such as: PP pall ring , PVDF pall ring, PTFE pall ring, PE, RPP, PVC, CPVC .

| Performance/Material | PE | PP | RPP | PVC | CPVC | PVDF | ||

| Density(g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 | ||

| Operation Temp(℃) | 90 | >100 | >120 | >60 | >90 | >150 | ||

| Chemical Corrosion resistance | Good | Good | Good | Good | Good | Good | ||

| Compression Strength(MPa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 | ||

Other material type is also available: metal pall ring packing, ceramic pall ring

Advantage of Polypropylene Pall Rings

- This pall ring packing has high Free Volume

- Low-Pressure Drop

- The random tower packing has low mass-transfer unit height

- High flooding point

- Small specific gravity

- High mass transfer efficiency

Application of Plastic Scrubber Packing

As a tower packing manufacturer, Naike is able to offer plastic pall ring for different usages.

- Absorbers

- Degassing

- Liquid/liquid extraction

- Water treatment

- Heat transfer