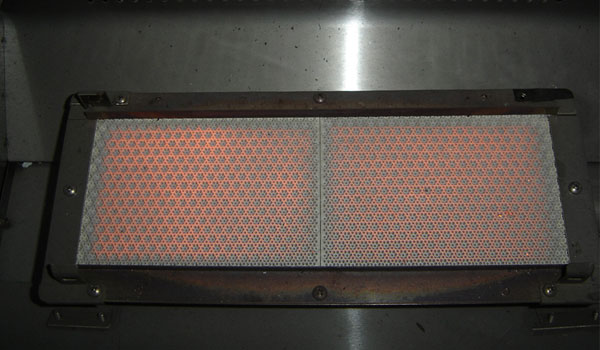

Infrared Ceramic Plate

Infrared Ceramic Plate

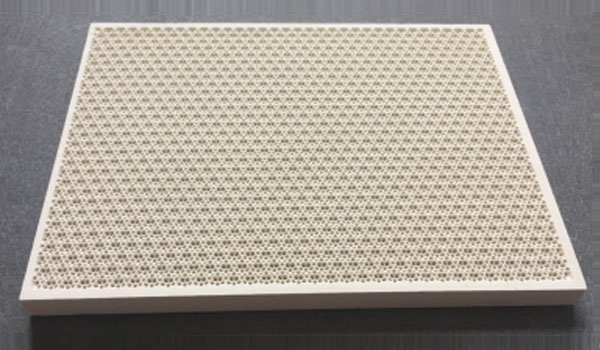

Honeycomb ceramic as the infrared combustion ceramic plate is made by the high purity cordierite material and used in the gas-fired stove. This product has good thermal shock resistance (no cracks on the product if the honeycomb ceramic with 1000 is in the water with 20 for 3 times), high mechanical strength (crushing strength is 20MPa on the top and 5MPa on the side), good endurance for high temperature, high resistance for erosion. If coated with a black catalyst, the honeycomb ceramic can transfer the heat by infrared radiation style and this combustion style has more outstanding advantages comparing to the normal gas-fired stove combustion as below:

描述

Parameters of Infrared Ceramic Plate

| Item | lndex | Specifications |

| Materials | Cordierite | We can provide you with the product by you desire |

| Water absorption | 50.40% | |

| Open Porosity | 61% | |

| Temperature softening | >1280℃ | |

| Specific gravity | 0. 9-1.10kg / cm3 | |

| cooking Surface Temperature | 1000-1200℃ | |

| CO release | ≤0.01% | |

| NOX release | ≤5ppm |

Overview of Infrared Ceramic Plate

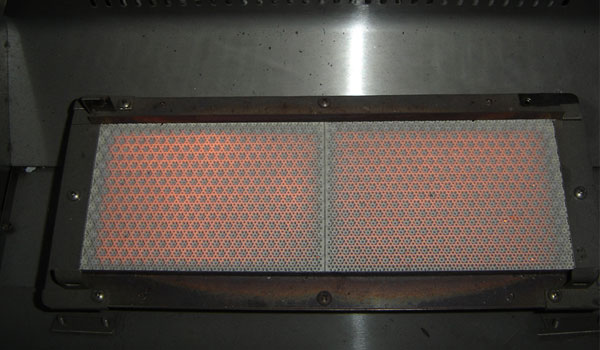

Saving gas more than 22%

Making Inflammable combustion

Decreasing the CO and NOx poisonous gas disposal and remove the factor for harm human body’s health.

Operating safety without wind influence when operating outdoors.

Our company’s infrared combustion ceramic plate honeycomb ceramic can be applied to different gas. When the customer makes the order for it, he or she should provide the parameters such as the product size, CPSI, cell shape, the gas style, the shape on the upper side.

If the customer needs the one with coated catalyst, he or she should provide the catalyst color.

Advantages of Infrared Ceramic Plate

- Save 20-50% energy consumption.

- Burn without flame, low noise.

- Reduce the formulation of such harmful gas as CO, NOx, etc by a large margin (more than 70%)

- Strong bearing of wind, using safely.