Packing Support/Grid Support

Packing Support/Grid Support

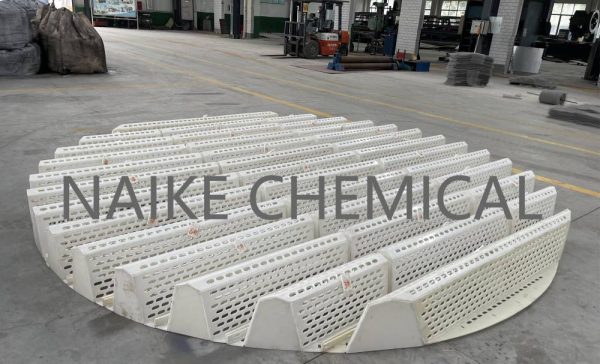

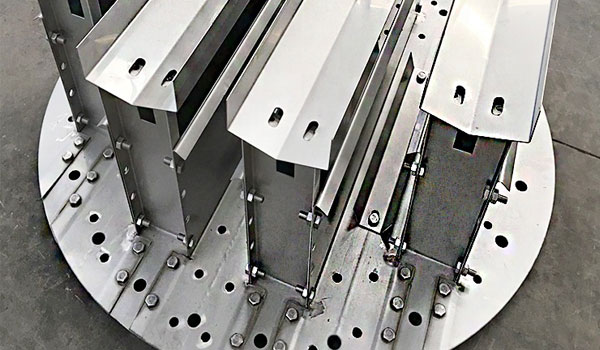

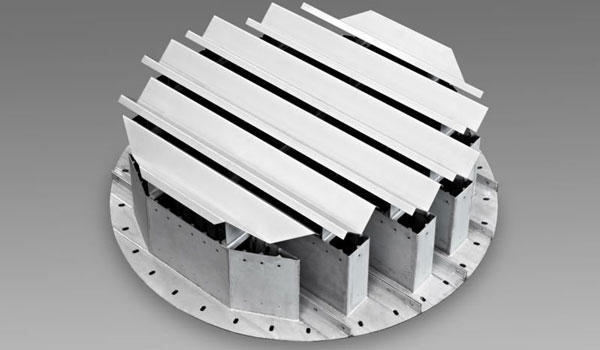

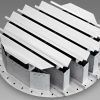

Multi-beam packing support, also named as hump support, as its name says, is made of several support beams. It can be made of metallic (carbon steel, stainless steel), plastic (PP, PVDF, CPVC), fibre-reinforced plastic (FRP) and ceramic materials. Multi-beam packing support is widely used in the absorption tower, washing tower and Distillation towers for random packing support. It has a high open area, extremely low-pressure drop and separated gas and liquid paths for high mass transfer efficiency.

描述

Advantages of Packing Support/Grid Support

The multi-beam packing support is regarded as one of the best random packing support grids.

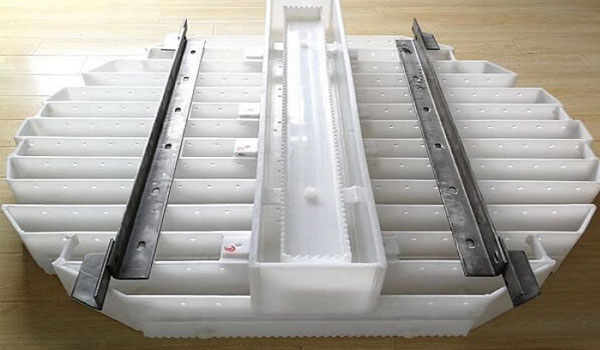

- 290 mm fixed width. It is assembled with several support beams, which has 290 mm width and 250–300 mm height.

- 10 mm fixed liquid drainage distance. Each neighbour beam is set at a 10 mm pitch for liquid drainage.

- Smaller than 10 mm opening size. The slot, square or round openings on the beam are smaller than 10 mm, which can prevent the 10 mm packing from leaking.

- Sectional design. Sectional design for easy transporting and installing and entering from manway.

- Separated channel for liquid and gas. The gas rises from the beam top and liquid flow down from the flat way to supply extremely low-pressure drop.

- With or without outer frame. The multi-beam packing support can be designed with or without outer frame to suit different diameters of the packing tower.

- Size and structure can be customized according to the customer’s drawings.

Material of Packing Support/Grid Support

carbon steel,Stainless steel including 304,304L,316,316L,321,410 etc.

According to the material,the multi-beam packing support have the metal support and plastic support.

Operating temperature of Packing Support/Grid Support

Stainless steel packing support < 300 °C.

Carbon steel packing support < 200 °C.

Plastic Packing support<100°C (PTFE for 250 °C)