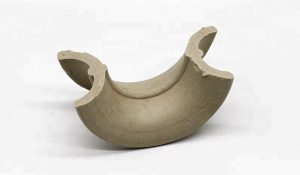

Ceramic Raschig Ring

Ceramic Raschig Ring

Ceramic Rasching Ring has excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids, organic acids and organic solvents except for hydrofluoric acid, and can be used in high or low-temperature conditions. Consequently, the application range is very wide. The packing can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in the chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

描述

Parameters of Ceramic Raschig Ring

| Name | Normal mm |

Diameter*Height* Thickness mm |

Surface area m2/m3 |

Void space % |

Bulk density kg/m3 |

No.elements per/m3 |

Packing factor m-1 |

| Raschig ring | ø16 | 16*16*3 | 250 | 66 | 820 | 178000 | 870 |

| ø25 | 25*25*3 | 147 | 78 | 510 | 42000 | 310 | |

| ø38 | 38*38*4 | 100 | 80 | 458 | 12000 | 195 | |

| ø50 | 50*50*5 | 80 | 81 | 465 | 5600 | 156 | |

| ø76 | 76*76*9 | 62 | 75 | 575 | 1700 | 147 |

Advantages of Ceramic Raschig Ring

- The ceramic tower packing is economical and low price.

- Simple structure.

- Acid and alkali resistance.

- High or low-temperature resistance.